When the jade rabbit 2 flew to the moon, there was the "artifact" of Foshan

Admin2021.12.23

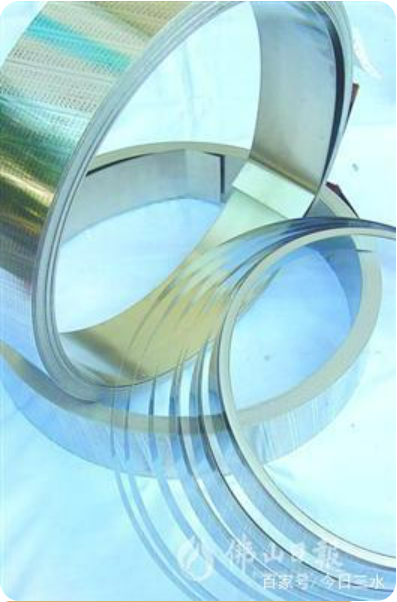

On January 3 this year, the jade rabbit II successfully landed on the back of the moon and sent back the first picture of the back of the moon in human history. In the whole huge aerospace project, there are thermal bimetallic and electrical contact materials developed and produced by Foshan Tongbao Precision Alloy Co., Ltd. (hereinafter referred to as "Tongbao precision").

Moreover, Tongbao precision products have been used in many national aerospace projects, such as Shenzhou VI, Tiangong I and Chang'e III. After more than 20 years of development, Tongbao precision has become one of the top three thermal bimetallic manufacturing enterprises in the world and the leader of domestic electrical contact materials, escorting the development of China's aerospace industry and becoming the pioneer of "people joining the army" of Foshan enterprises.

Excellent product

It has been applied to aerospace projects

When the electrical load at home is overloaded, it will automatically trip and cut off the power supply. The key material is the hot bimetallic sheet in the electric box. Thin thermal bimetallic sheets are not only used in various household appliances such as rice cookers, coffee machines and hot water pots, as well as various low-voltage appliances such as circuit breakers and contactors, but also an indispensable part of aerospace vehicles. Since 1996, Tongbao precision products have been used in aerospace projects.

"Tongbao precision, founded in 1993, seized the national demand for thermal bimetals at the early stage of its establishment and took the lead in R & D and production of relevant products in China." Lu Xiaodong, general manager of Tongbao precision, recalled that through the introduction of advanced production equipment and continuous innovation and breakthrough, the enterprise quickly gained a foothold in the market.

As the first high-precision special metal enterprise in China, the output of Tongbao precision thermal bimetallic is in the forefront of the world. "In the domestic market, for every three hot bimetallic sheets, one comes from Tongbao precision." Lu Xiaodong introduced that the products are provided to domestic well-known brands such as Haier, Midea, Gree, Jiuyang, Chint and Delixi. The company also has long-term cooperation with the world's top 500 enterprises such as Schneider, Siemens and abb.

It is precisely because of its excellent product quality and leading technology advantages that Tongbao precision can deeply participate in the "people join the army" project. "Around 2000, the national space project team took the initiative to come to the door and hoped to strengthen cooperation with us." Lu Xiaodong said that over the years, thermal bimetals and electrical contact materials produced by enterprises have been frequently used in aerospace projects.

"Starting from Shenzhou VI, after each rocket launch, Tongbao precision will receive a model and a thank-you letter, which is not only a reward for us, but also an encouragement to the enterprise." Lu Xiaodong said with a smile.

Continuous innovation

The annual R & D cost shall be at least 20 million yuan

The aerospace project has extremely strict requirements for the use of products, which also promotes Tongbao precision's tireless pursuit of excellence.

In Lu Xiaodong's view, constant experiment and constant exploration have become commonplace. For example, in order to catch up with and surpass the international advanced level, Tongbao precision has introduced controllable atmosphere thermal composite technology and its production line. In order to master its core technology as soon as possible, Tongbao precision technicians study it day and night.

Huo Ruihong, deputy general manager of Tongbao precision, introduced that in order to meet the requirements of Aerospace Engineering, the enterprise has formulated strict production processes, and carefully controlled all links such as inspection, inspection and packaging during the production process and subsequent products.

"Tongbao precision has also established a physical property testing room and a physical and chemical analysis room to strictly control product quality." Huo Ruihong said that Tongbao precision has obtained the quality, environment, occupational health and safety management system certification of ISO9001, ISO14001 and OHSAS18001 and the secondary measurement assurance system of Guangdong Province. Its products comply with the provisions of the EU ROHS directive.

"The product reliability of Tongbao precision has reached zero ppm at most, which is equivalent to 1 million products without any defective products." Lu Xiaodong said. The so-called reliability index is a very important quality index to measure thermal bimetallic and electrical contact materials. In the harsh environment, the more important it can be. For example, when the launch rocket is in the state of extremely high temperature and high speed, it will have high requirements for the reliability of the materials used.

Continuous R & D investment and cultivation of innovative talents ensure that Tongbao precision provides higher quality products for aerospace projects. "Every year, the R & D cost invested by Tongbao precision is at least 20 million yuan." Lu Xiaodong said that the company has a new functional material engineering technology R & D center composed of doctors, postgraduates and senior engineers, and has long cooperated with universities and scientific research institutes to carry out industry university research projects.

Overall planning / Foshan Daily reporter Wen Qian

Text / figure Foshan Daily reporter LV Jinsheng intern Lin Ze correspondent Li Guofeng

Editor / Chen Lingling of Foshan daily