Thermostatic Bimetal Parts and Assemblies

The Application of Bimetals

1. Following factors should be considered in designing a bimetal element: 2. Bimetal Types and Specifications.

a. Current level for element to stand a. Classified by using temperature: ● low temperature, ● medium temperature, ● high temperature.

b. Operating temperature; b. Bimetal type, size and shape are dependent on the value calculated by motion space, displacement,

c. Maximum temperature for element to stand ; current level and release force: ● High-sensitive type, ● Medium-sensitive type, ● Low-sensitive type.

d. The requirements of the displacement and power; c. In line with the calculated outcome to make the installation test.

e. Space constraint; 1) The temperature range of application is a little larger than the linear temperature range. Within this

f. Working condition, etc. range, bimetal with free deformation will not present the residual deformation. While beyond that range,

he bimetal material’s expansion coefficient will have a great change so that the sensitive of the bimetal

will be decreased. But it still can be used. And this temperature is generally lower than the Curie point,

of the material, since the material structure and performance will change once reached the Curie point.

2) According the motion space,displacement, current level, tripping force, and etc, to figure out the

bimetal type, dimension and shape.

Bimetal Element Forming

Bimetal elements are usually punched forming, some of them still have to be pressed forming during the manufacture process. In addition, burr or folded edge should be avoided in the punching process. Once burr or folded edge occurred, it will decrease the heat deformation of bimetal. When the width is 20% larger than the length, the transverse bending which appeared in the element heating process also will decrease the heat deformation of bimetal. That should be considered in the design.

To ensure the uniform performance of bimetal material, different rolling or stamping elements should not be mix used.In the manufacture process, press forming should be perpendicular to the rolling direction so that to acquire higher strength, and avoid the minor radius press forming. Curving radius should 1.5 times thicker than the material’s thickness.

Due to the high sensitivity thermal bimetal active layer material is high-manganese which is more brittle. In the process of bending, we should try to bend the brittle side inby to avoid cracking. When the active layer must be outside of the bend, you can reduce the amount of cold deformation to decrease the material hardness to avoid cracking.

The atlas

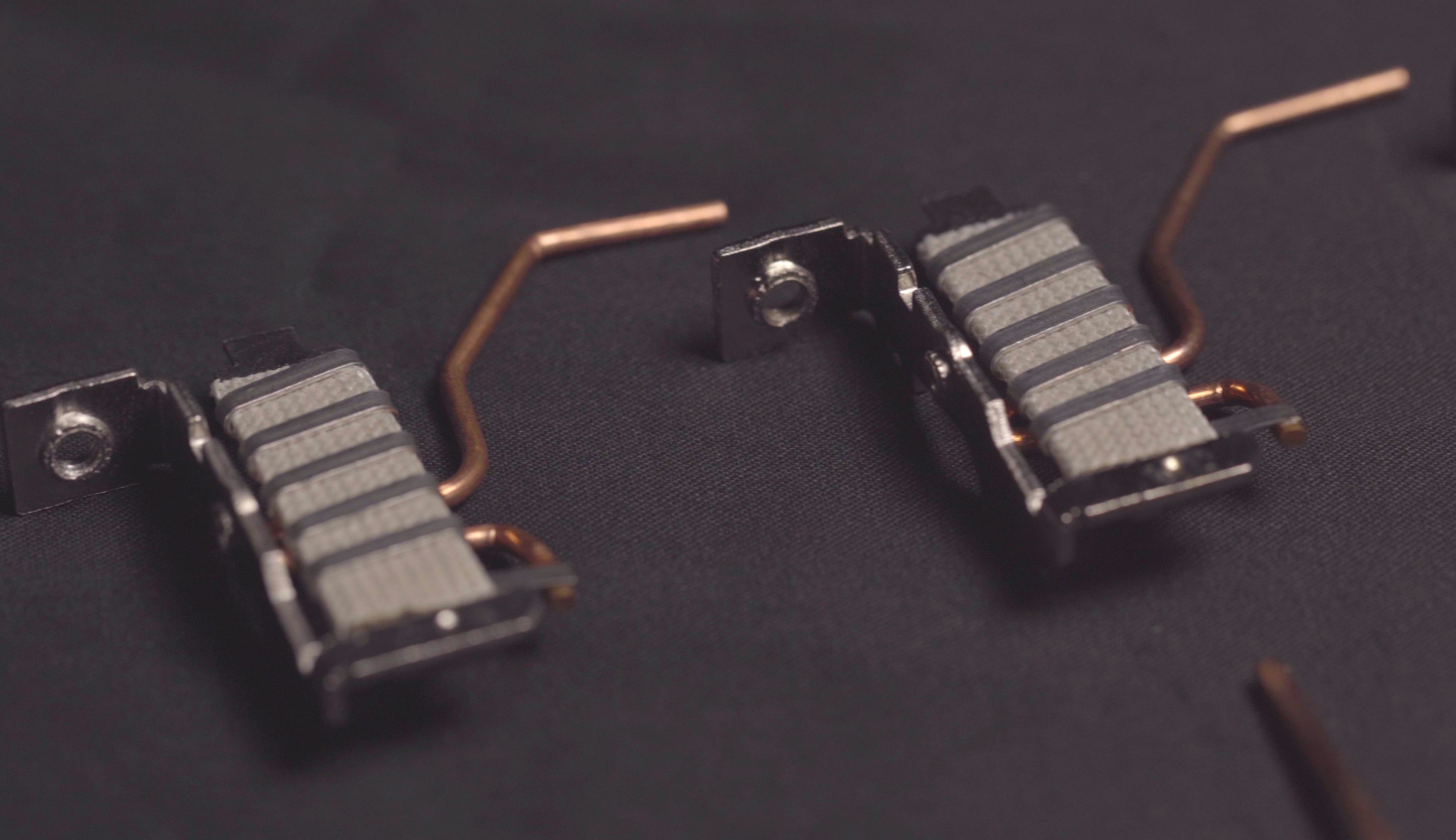

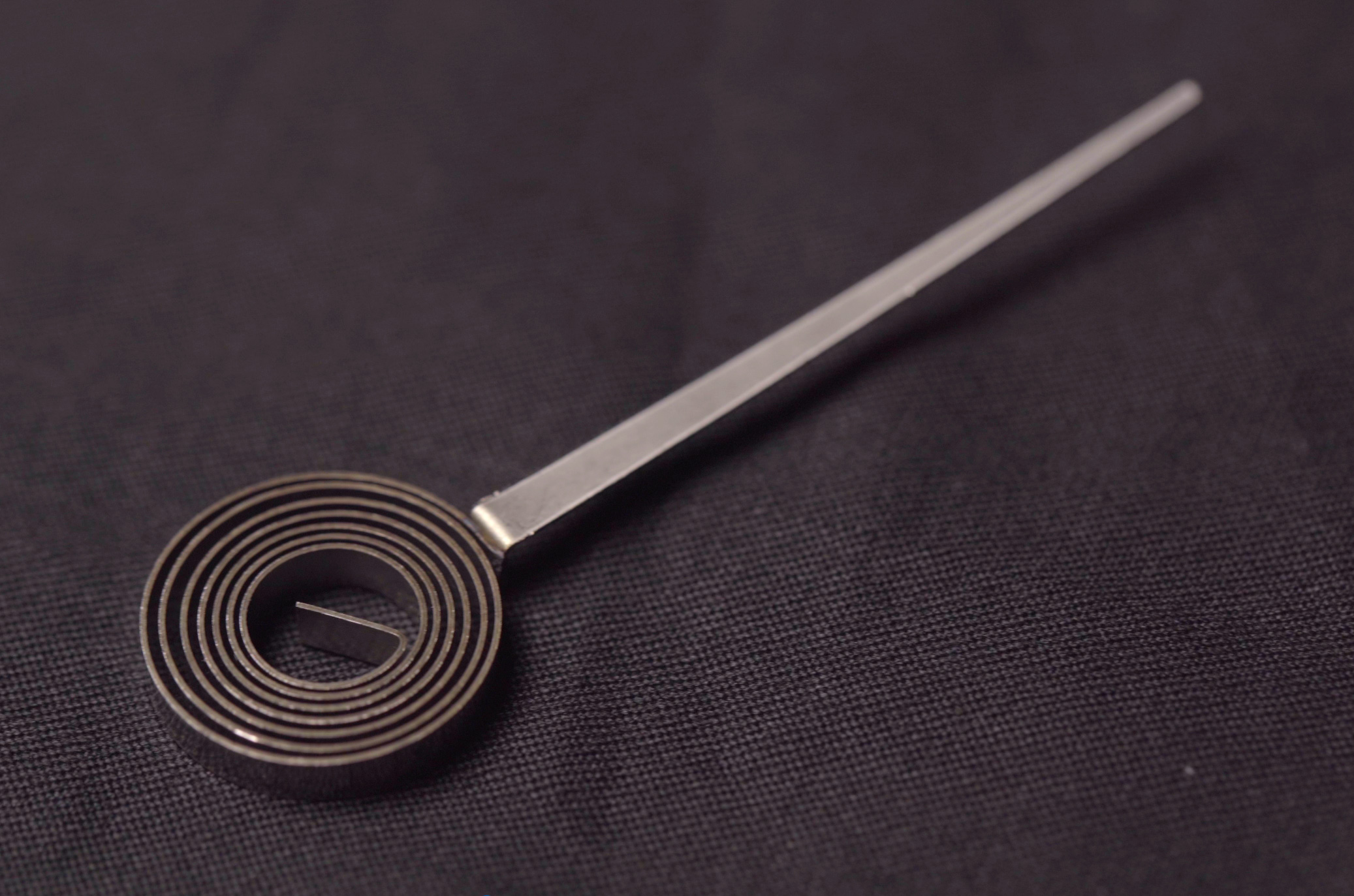

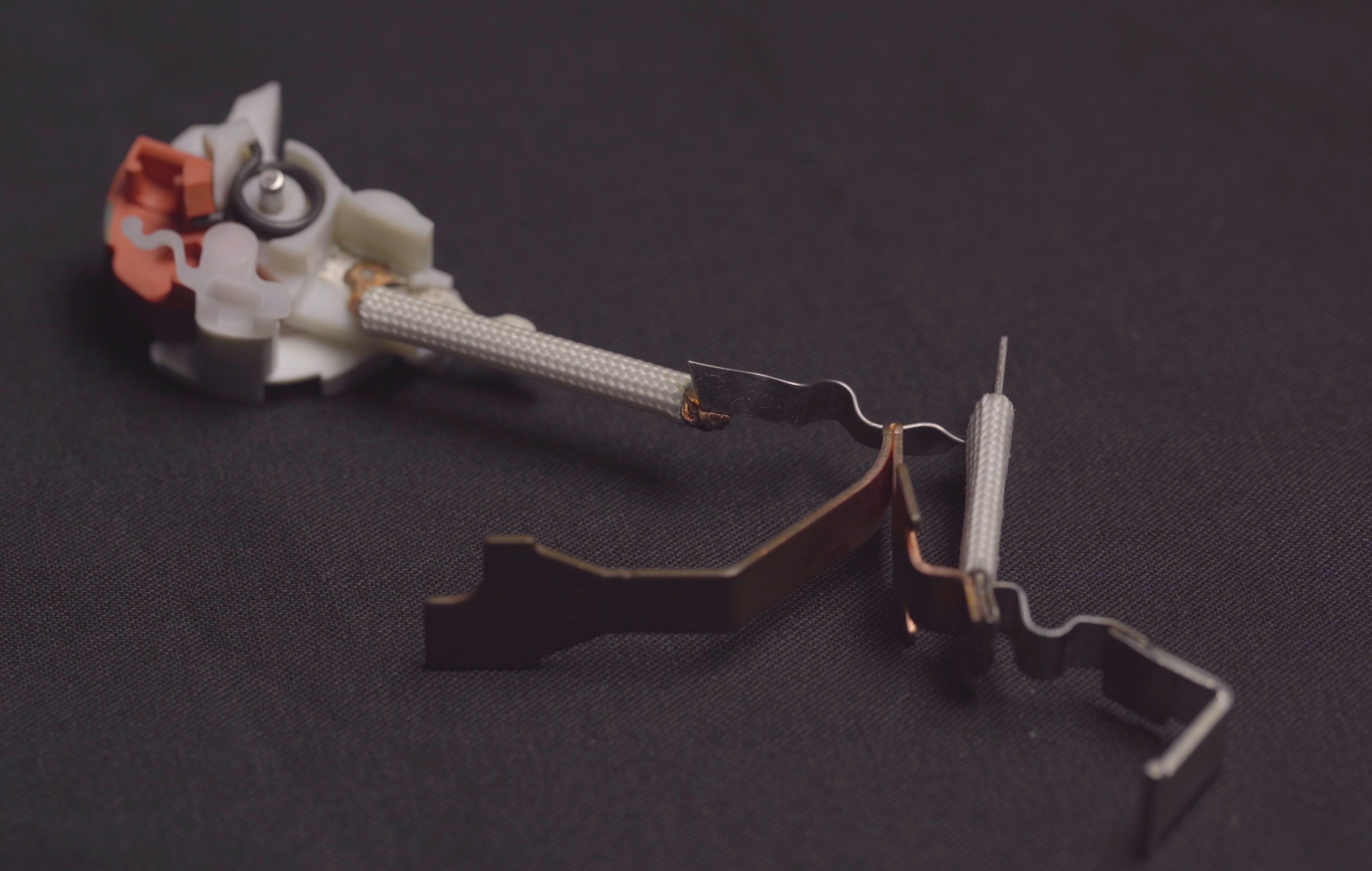

Parts and Assemblies

Parts and Assemblies

Parts and Assemblies

Download of related materials